Understanding Container Liners: An Overview

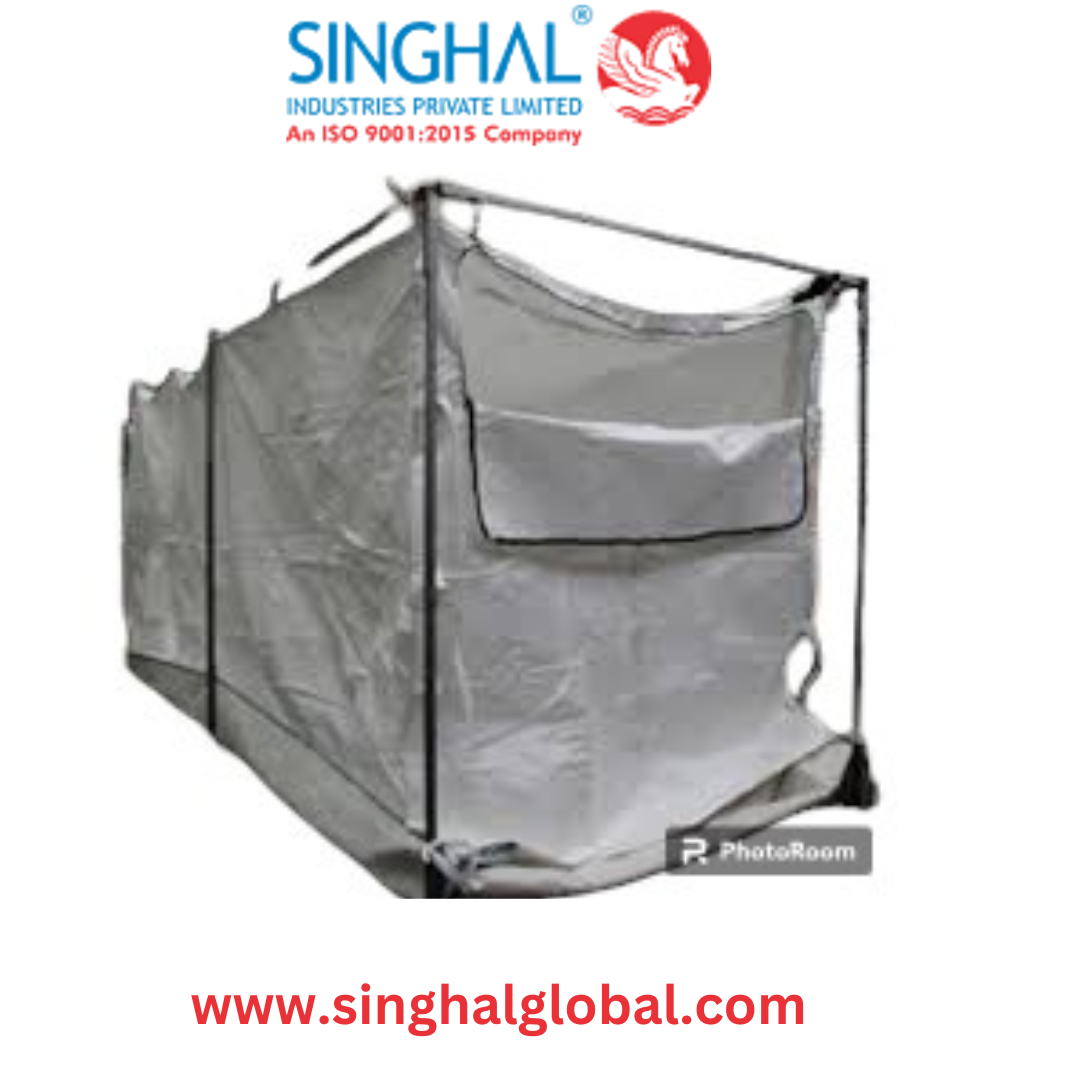

Container liners are specialized protective coverings designed to provide an effective barrier during the transportation and storage of bulk goods. With the rise in global trade and shipping, these liners have gained immense importance, particularly in the shipping industry. The role of container liners has expanded, making them a staple in securing goods against moisture, contamination, and physical damage. Understanding the nuances of container liners, including their design and material composition, is crucial for industries relying on them for safe shipping.

Container liners are typically made from polyethylene or woven fabric that offers durable solutions based on specific cargo needs. They not only serve as physical barriers but also prevent the loss of product due to spillage or contamination during transit. Container liners can be customized according to the dimensions of shipping containers, catering to various types of goods such as grains, chemicals, and construction materials. Thus, the expertise of Container Liners Manufacturers becomes essential for delivering high-quality products tailored to unique customer needs.

Materials Used in Container Liners

Exploring the Types of Materials

Container liners are primarily made from two types of materials—woven polypropylene and polyethylene films. Woven polypropylene liners are particularly popular for their strength and resistance to moisture. These liners are constructed by weaving strands into a durable fabric, which can withstand handling and rough conditions during transportation. The adaptability of woven materials makes them perfect for products like granulated substances and bulk powders where structural integrity is vital.

On the other hand, polyethylene liners are smoother and often utilized for liquid and solid commodities that require a cleaner transportation method. These types of liners are generally used for hazardous goods due to their ability to provide a moisture-proof barrier while preventing leakage. The choice of material plays a significant role in determining not only the integrity of the cargo but also compliance with safety regulations. Therefore, understanding the characteristics of various materials is essential for making informed decisions about the right container liner for specific goods.

Applications of Container Liners in Various Industries

Versatility Across Sectors

The versatility of container liners spans across various industries, including agriculture, pharmaceuticals, and construction. In the agricultural sector, container liners are predominantly used for transporting grains, seeds, and fertilizers. Their ability to prevent moisture ingress protects these goods from spoilage during transit, ensuring that products maintain their quality upon arrival.

In the pharmaceutical industry, sterile and contamination-free shipping is critical. Here, container liners facilitate the secure transport of sensitive products and chemicals, meeting stringent health and safety regulations. Similarly, in construction, bulk materials such as cement and aggregates benefit from container liners, which shield them from external elements that might compromise their quality.

The application spectrum of container liners illustrates their necessity in maintaining product integrity during shipping and storage. With the guidance and services from reputable Container Liners Suppliers, companies can ensure that their products arrive at their destinations in optimal condition.

Key Benefits of Using Container Liners

Enhancing Logistics and Supply Chain Efficiency

Utilizing container liners provides numerous advantages that streamline logistics and enhance supply chain efficiency. Primarily, container liners protect against moisture, dirt, and contamination, leading to reduced product losses. They also facilitate the loading and unloading process, as the liners can be easily sealed and handled, reducing labor costs associated with managing loose cargo.

Furthermore, by maintaining the quality and safety of the transported goods, container liners contribute to improved customer satisfaction. Customers receive products in acceptable condition, thus maintaining trust in suppliers and manufacturers. These efficiencies are beneficial not only to the shipping companies but also to end-users, who are depending on the integrity of the products they receive.

Moreover, container liners are cost-effective. They minimize damage to products during transit, which can significantly reduce insurance claims and related expenses. A company that optimizes the use of container liners can see marked increases in both efficiency and profitability over time.

Regulatory Standards for Container Liners

Complying with Trade Requirements

The logistics and shipping industries have a plethora of regulations governing the transportation of goods. Container liners must comply with various national and international standards, especially when shipping hazardous materials. Regulatory bodies impose these requirements to ensure safety, traceability, and environmental compliance.

Ensuring compliance involves working closely with reputable Container Liners Manufacturers to understand the necessary certifications and quality standards. By investing in high-quality and regulation-compliant liners, companies protect themselves from liability and potential fines associated with non-compliance. The importance of adhering to regulatory standards cannot be overstated; failure to comply can lead to severe repercussions for businesses engaged in international trade.

A dedicated approach to understanding these regulations enhances a company’s performance and reputation. Meeting the required standards is not only a legal obligation but also a pathway to establishing trust with partners across the globe.

Emerging Technologies in a Container Liners Market

Innovation Driving Development

The evolution of container liners is being significantly influenced by advancements in technology. Innovations such as smart logistics and IoT integration are paving the way for more sophisticated container liner solutions. Companies are now able to monitor the conditions within shipping containers in real-time, using sensors that track temperature, humidity, and other critical parameters.

This technology acts as an additional layer of protection for sensitive goods, alerting operators to potential risks before they escalate. As a result, buyers are becoming more demanding, looking for liners that offer integrated technology for added safety and efficiency.

Additionally, the shift towards sustainability is leading to the development of eco-friendly container liners. Manufacturers are exploring recyclable materials and biodegradable alternatives, responding to the increasing consumer demand for sustainable practices. As industries shift to greener alternatives, embracing these innovations is essential.

Conclusion: The Future of Container Liners

Container liners are essential tools in the logistics and shipping sectors, providing significant advantages that enhance efficiency, compliance, and product protection. As companies continue to emphasize sustainability and smart logistics, the demand for innovative and compliant container solutions is poised to grow. The reliance on high-quality container liners produced by reputable Container Liners Manufacturers will ensure that goods reach their destinations without loss or damage.

In conclusion, considering the significance of container liners for effective transportation, it’s vital for businesses to partner with reliable Container Liners Suppliers who understand the complexities of industry needs. Investing in the right materials, technology, and compliance guarantees that products remain unscathed during shipping. For companies in search of Container Liner Sheet In India, aligning with experienced suppliers will be key to meeting logistical and regulatory challenges.

Frequently Asked Questions

- What materials are commonly used in container liners?

Container liners are primarily made from woven polypropylene and polyethylene films. Woven polypropylene is known for its strength and moisture resistance, while polyethylene liners are ideal for liquid and sensitive cargo. - How do container liners protect against contamination?

Container liners create a barrier that prevents moisture, dirt, and contaminants from damaging cargo. This is crucial for preserving the quality and safety of the transported goods. - What standards should container liners adhere to?

Container liners must comply with a range of national and international regulations, particularly when transporting hazardous materials. Working with recognized manufacturers ensures compliance with these standards. - Are there eco-friendly options for container liners?

Yes, the industry is seeing a rise in demand for eco-friendly container liners. Manufacturers are developing biodegradable and recyclable options in response to the increasing emphasis on sustainability.