Report Overview:

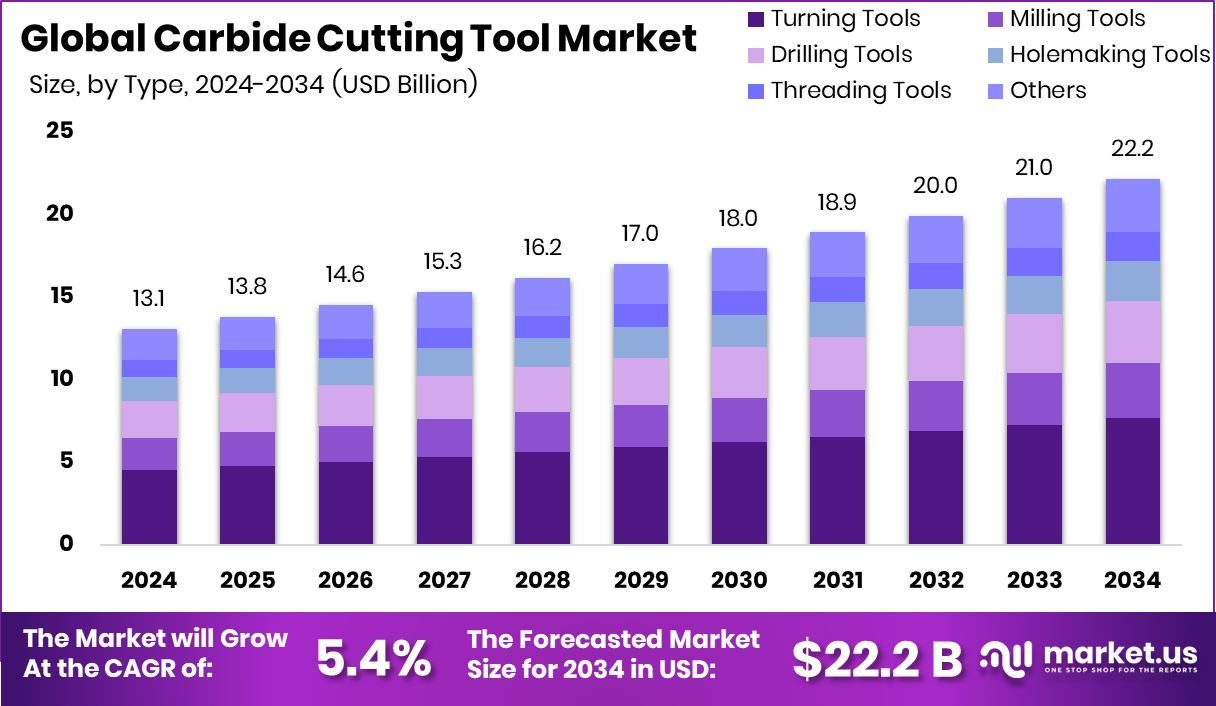

The global carbide cutting tool market is poised for significant growth, climbing from approximately USD 13.1 billion in 2024 to an anticipated USD 22.2 billion by 2034. This represents a solid compound annual growth rate (CAGR) of 5.4% over the period.

Key Takeaways:

Global Carbide Cutting Tool Market is expected to be worth around USD 22.2 billion by 2034, up from USD 13.1 billion in 2024, and grow at a CAGR of 5.4% from 2025 to 2034.

In 2024, turning tools dominated the carbide cutting tool market, holding a 34.6% share.

Coated carbide cutting tools accounted for 77.3% of the market, providing enhanced durability.

Machine-based carbide cutting tools led the industry with an 82.3% market share in 2024.

Tungsten carbide materials represented 72.4% of the carbide cutting tool market by material type.

Sintering accounted for 53.7% of the market, enhancing tool performance and wear resistance.

The automotive sector emerged as a key driver, contributing 32.7% to the market share.

In 2024, North America’s dominance reflected strong industrial demand, totaling USD 6.1 Bn.

Download Exclusive Sample Of This Premium Report:

https://market.us/report/carbide-cutting-tool-market/free-sample/

Key Market Segments:

By Type

Turning Tools

Milling Tools

Drilling Tools

Holemaking Tools

Threading Tools

Others

By Coating Type

Coated

Non-coated

By Configuration

Hand-based

Machine-based

By Material

Tungsten Carbide

Titanium Carbide

Tantalum Carbide

By Process

Forging

Casting

Sintering

Others

By End-use

Automotive

Aerospace

Construction

Oil and Gas

Heavy Machinery

Medical

Electronics

Others

Drivers:

Rising adoption of automated machining, advancements in sensor-equipped (IoT-enabled) tools, and the push toward precision manufacturing are top drivers. These technologies enhance tool life, accuracy, and productivity, spurring market growth

Opportunities:

Aerospace, defense, and emerging electric vehicle (EV) markets are hungry for durable, precise tools. With government initiatives like India’s “Make in India” and Production Linked Incentive schemes backing domestic capabilities, these sectors offer fertile ground for expansion

Restraints:

High production costs from raw material sourcing (especially tungsten carbide), coating, and sintering pose a barrier. These factors particularly impact SMEs and price-sensitive buyers

Trends:

Material price volatility (especially tungsten), supply chain disruptions, and competition from alternative tools (like ceramics or high-speed steel) could threaten market stability

Market Key Players:

OSG Corporation

TaeguTec LTD

Sandvik AB

Birla Precision Technologies Limited

Forbes & Company Limited

Gleason Corporation

HITTCO Tools Limited

Plansee Group

Kennametal Inc

Sumitomo Electric Industries Ltd

Guhring Ltd

Fullerton Tool Company Inc

YG-1 Co Ltd

Allied Machine & Engineering Corp

KYOCERA SGS

Other Key Players

Report Overview:

The global carbide cutting tool market is poised for significant growth, climbing from approximately USD 13.1 billion in 2024 to an anticipated USD 22.2 billion by 2034. This represents a solid compound annual growth rate (CAGR) of 5.4% over the period.

Key Takeaways:

-

- Global Carbide Cutting Tool Market is expected to be worth around USD 22.2 billion by 2034, up from USD 13.1 billion in 2024, and grow at a CAGR of 5.4% from 2025 to 2034.

- In 2024, turning tools dominated the carbide cutting tool market, holding a 34.6% share.

- Coated carbide cutting tools accounted for 77.3% of the market, providing enhanced durability.

- Machine-based carbide cutting tools led the industry with an 82.3% market share in 2024.

- Tungsten carbide materials represented 72.4% of the carbide cutting tool market by material type.

- Sintering accounted for 53.7% of the market, enhancing tool performance and wear resistance.

- The automotive sector emerged as a key driver, contributing 32.7% to the market share.

- In 2024, North America’s dominance reflected strong industrial demand, totaling USD 6.1 Bn.

![]()

Download Exclusive Sample Of This Premium Report:

https://market.us/report/carbide-cutting-tool-market/free-sample/

Key Market Segments:

By Type

- Turning Tools

- Milling Tools

- Drilling Tools

- Holemaking Tools

- Threading Tools

- Others

By Coating Type

- Coated

- Non-coated

By Configuration

- Hand-based

- Machine-based

By Material

- Tungsten Carbide

- Titanium Carbide

- Tantalum Carbide

By Process

- Forging

- Casting

- Sintering

- Others

By End-use

- Automotive

- Aerospace

- Construction

- Oil and Gas

- Heavy Machinery

- Medical

- Electronics

- Others

Drivers:

Rising adoption of automated machining, advancements in sensor-equipped (IoT-enabled) tools, and the push toward precision manufacturing are top drivers. These technologies enhance tool life, accuracy, and productivity, spurring market growth

Opportunities:

Aerospace, defense, and emerging electric vehicle (EV) markets are hungry for durable, precise tools. With government initiatives like India’s “Make in India” and Production Linked Incentive schemes backing domestic capabilities, these sectors offer fertile ground for expansion

Restraints:

High production costs from raw material sourcing (especially tungsten carbide), coating, and sintering pose a barrier. These factors particularly impact SMEs and price-sensitive buyers

Trends:

Material price volatility (especially tungsten), supply chain disruptions, and competition from alternative tools (like ceramics or high-speed steel) could threaten market stability

Market Key Players:

- OSG Corporation

- TaeguTec LTD

- Sandvik AB

- Birla Precision Technologies Limited

- Forbes & Company Limited

- Gleason Corporation

- HITTCO Tools Limited

- Plansee Group

- Kennametal Inc

- Sumitomo Electric Industries Ltd

- Guhring Ltd

- Fullerton Tool Company Inc

- YG-1 Co Ltd

- Allied Machine & Engineering Corp

- KYOCERA SGS

- Other Key Players

Report Overview:

The global carbide cutting tool market is poised for significant growth, climbing from approximately USD 13.1 billion in 2024 to an anticipated USD 22.2 billion by 2034. This represents a solid compound annual growth rate (CAGR) of 5.4% over the period.

Key Takeaways:

-

- Global Carbide Cutting Tool Market is expected to be worth around USD 22.2 billion by 2034, up from USD 13.1 billion in 2024, and grow at a CAGR of 5.4% from 2025 to 2034.

- In 2024, turning tools dominated the carbide cutting tool market, holding a 34.6% share.

- Coated carbide cutting tools accounted for 77.3% of the market, providing enhanced durability.

- Machine-based carbide cutting tools led the industry with an 82.3% market share in 2024.

- Tungsten carbide materials represented 72.4% of the carbide cutting tool market by material type.

- Sintering accounted for 53.7% of the market, enhancing tool performance and wear resistance.

- The automotive sector emerged as a key driver, contributing 32.7% to the market share.

- In 2024, North America’s dominance reflected strong industrial demand, totaling USD 6.1 Bn.

Download Exclusive Sample Of This Premium Report:

https://market.us/report/carbide-cutting-tool-market/free-sample/Key Market Segments:

By Type

- Turning Tools

- Milling Tools

- Drilling Tools

- Holemaking Tools

- Threading Tools

- Others

By Coating Type

- Coated

- Non-coated

By Configuration

- Hand-based

- Machine-based

By Material

- Tungsten Carbide

- Titanium Carbide

- Tantalum Carbide

By Process

- Forging

- Casting

- Sintering

- Others

By End-use

- Automotive

- Aerospace

- Construction

- Oil and Gas

- Heavy Machinery

- Medical

- Electronics

- Others

Drivers:

Rising adoption of automated machining, advancements in sensor-equipped (IoT-enabled) tools, and the push toward precision manufacturing are top drivers. These technologies enhance tool life, accuracy, and productivity, spurring market growth

Opportunities:

Aerospace, defense, and emerging electric vehicle (EV) markets are hungry for durable, precise tools. With government initiatives like India’s “Make in India” and Production Linked Incentive schemes backing domestic capabilities, these sectors offer fertile ground for expansion

Restraints:

High production costs from raw material sourcing (especially tungsten carbide), coating, and sintering pose a barrier. These factors particularly impact SMEs and price-sensitive buyers

Trends:

Material price volatility (especially tungsten), supply chain disruptions, and competition from alternative tools (like ceramics or high-speed steel) could threaten market stability

Market Key Players:

- OSG Corporation

- TaeguTec LTD

- Sandvik AB

- Birla Precision Technologies Limited

- Forbes & Company Limited

- Gleason Corporation

- HITTCO Tools Limited

- Plansee Group

- Kennametal Inc

- Sumitomo Electric Industries Ltd

- Guhring Ltd

- Fullerton Tool Company Inc

- YG-1 Co Ltd

- Allied Machine & Engineering Corp

- KYOCERA SGS

- Other Key Players

-