Signage plays a crucial role in branding, marketing, and guiding customers. While the final product is visually appealing, the journey from concept to installation is a meticulous process. Understanding the signage fabrication workflow offers insight into the precision, creativity, and expertise involved. Signage manufacturers follow a structured approach to ensure every sign is durable, accurate, and aligned with client expectations.

Conceptualization and Design

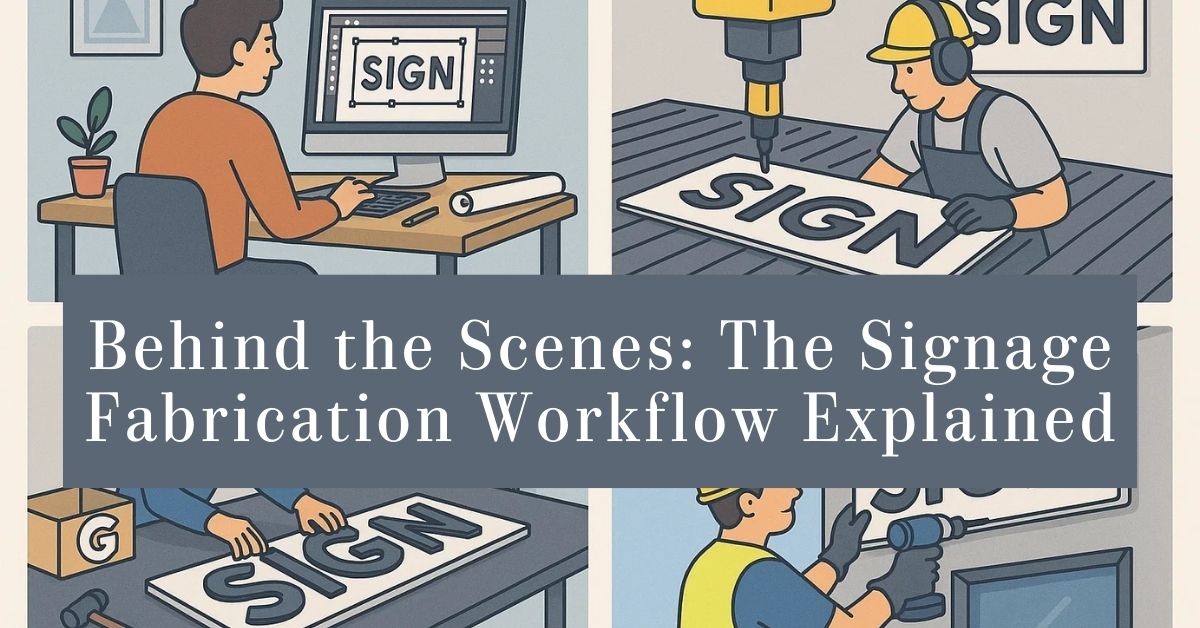

The journey of any sign begins with an idea. Signage Chennai collaborates closely with clients to understand their requirements, brand identity, and the environment where the signage will be displayed. This phase involves brainstorming, sketching initial designs, and selecting appropriate materials. Digital tools such as computer-aided design (CAD) software are commonly used to create detailed mockups. These mockups allow clients to visualize the final product and suggest modifications before production begins. A well-planned design phase saves time and reduces the risk of errors in later stages.

Design considerations go beyond aesthetics. Visibility, readability, and durability are critical factors. For instance, outdoor signage must withstand weather conditions, while indoor signs should harmonize with the interior décor. Signage manufacturers leverage their experience to balance creativity with functionality, ensuring the sign is not only visually striking but also practical for its intended purpose.

Material Selection and Preparation

Once the design is finalized, the next step is selecting materials. The choice of materials depends on the type of sign, location, and budget. Common materials include acrylic, metal, wood, PVC, and vinyl. Each material has distinct properties, such as flexibility, strength, and weather resistance, which influence the fabrication process.

Material preparation is a crucial stage. Sheets of metal may need to be cut and bent, acrylic panels polished, and vinyl carefully measured. Precision is essential because even slight deviations can affect the final product. Signage manufacturers use advanced machinery, including laser cutters, CNC routers, and heat bending machines, to ensure accuracy and maintain consistency across multiple units.

Fabrication and Assembly

Fabrication is where the design begins to take tangible form. This stage involves cutting, shaping, engraving, and printing the selected materials. Laser cutting and CNC machines allow for intricate designs, while handcrafting may be applied for unique or artistic elements. Metal etters Chennai often combine automated processes with skilled craftsmanship to achieve a perfect balance of precision and creativity.

Assembly follows fabrication. Components such as letters, logos, and structural supports are joined together using adhesives, screws, or welding. For illuminated signs, wiring and LED installation are integrated during assembly. Proper alignment and structural integrity are critical to ensure the sign functions safely and looks professional. At this stage, attention to detail can make a significant difference in the overall quality and durability of the sign.

Finishing and Quality Control

After assembly, the sign undergoes finishing touches. This may include painting, polishing, lamination, or applying protective coatings. Finishing enhances aesthetics while also providing durability, especially for outdoor signs exposed to environmental elements. Signage manufacturers use specialized techniques to achieve uniform finishes, vibrant colors, and smooth textures that meet client expectations.

Quality control is a vital step before the sign is dispatched. Each sign is inspected for defects, alignment issues, and adherence to design specifications. Electrical components, if present, are tested to ensure proper illumination. Signage manufacturers maintain high standards to ensure that every sign meets safety requirements, longevity expectations, and visual appeal. This stage guarantees that clients receive a product that is both functional and visually striking.

Packaging and Delivery

Once the sign passes quality checks, it is carefully packaged to prevent damage during transportation. Protective materials such as foam, bubble wrap, or custom crates may be used depending on the sign’s size and fragility. Signage manufacturers coordinate logistics to deliver the product safely and on schedule.

For large-scale or complex installations, some manufacturers provide on-site installation services. This ensures the sign is positioned correctly, secured safely, and connected to electrical sources if needed. Proper installation enhances the sign’s visibility and impact while maintaining structural integrity.

The Role of Technology in Modern Signage Fabrication

Modern signage fabrication heavily relies on technology to improve efficiency, accuracy, and creativity. From digital design tools to automated cutting machines and LED programming, technology streamlines every step of the workflow. Signage manufacturers leverage these innovations to produce high-quality signs faster and with greater precision than ever before.

Moreover, software solutions allow manufacturers to simulate lighting effects, material finishes, and size proportions digitally. This helps clients make informed decisions and reduces costly mistakes during fabrication. The integration of technology also enables better scalability, allowing manufacturers to produce multiple signs with consistent quality for larger projects.

Conclusion

The signage fabrication workflow is a complex and precise process that requires expertise, creativity, and attention to detail. From initial concept and design to material selection, fabrication, assembly, finishing, and installation, every step is carefully managed by skilled name board makers in Chennai. The combination of craftsmanship, technology, and quality control ensures that the final product is not only visually appealing but also durable and functional.

Understanding this workflow highlights the professionalism behind every sign and emphasizes why partnering with experienced signage manufacturers is essential for achieving impactful, high-quality signage solutions.